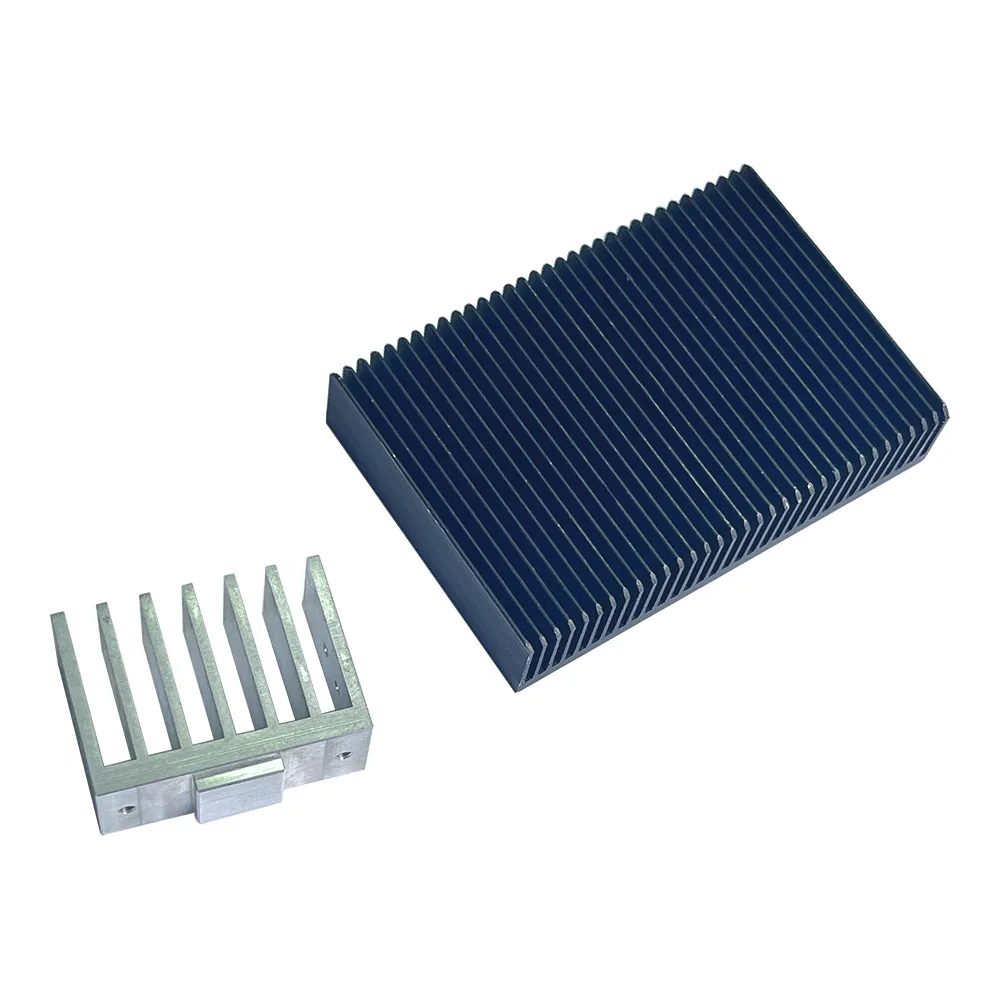

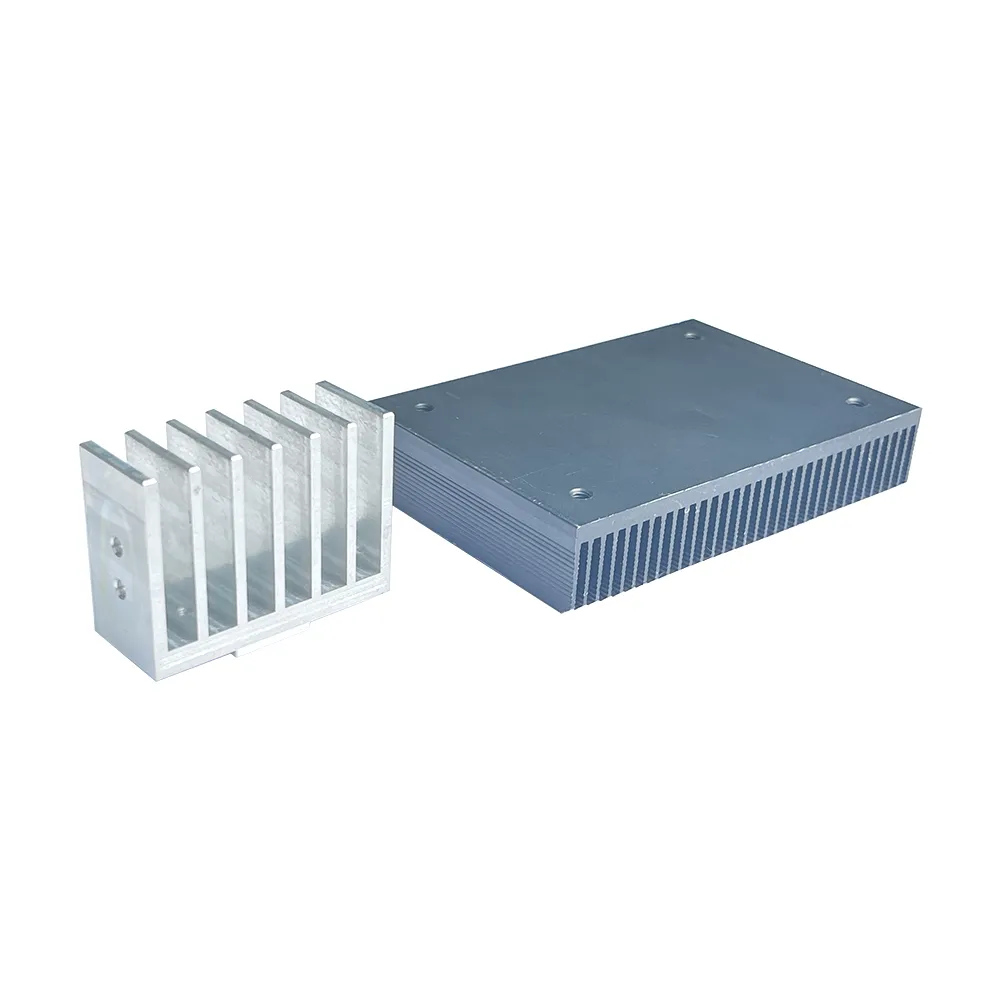

As the core component of a heat sink, the heat sink plays a crucial role in significantly increasing its contact area with air. The heat sink manufactured through CNC precision machining technology further enhances this performance, thereby accelerating heat dissipation.

At the same time, the heat dissipation base tightly adheres to the heating element, not only firmly fixing the heat sink, but also ensuring efficient heat conduction between the heat sink and electronic components, further optimizing the overall heat dissipation performance. The application of CNC technology makes this process more precise and efficient.

Product Detials

Machinable materials:

There are various materials for heat sinks, including aluminum alloy, brass, bronze, and copper, which are commonly used. There are differences in thermal conductivity, cost, and processing difficulty among heat sinks made of different materials.

Ranked in descending order of thermal conductivity, they are silver, copper, aluminum, and steel. However, due to the high cost of silver, it is not commonly used in practical applications.

Copper has excellent thermal conductivity, but it is expensive, difficult to process, and heavy in weight. Aluminum alloy has become a commonly used heat sink material for ordinary users due to its low price, light weight, and easy processing

Application area

Heat sinks are widely used in various electronic devices, automotive engines, and other mechanical equipment that require heat dissipation.

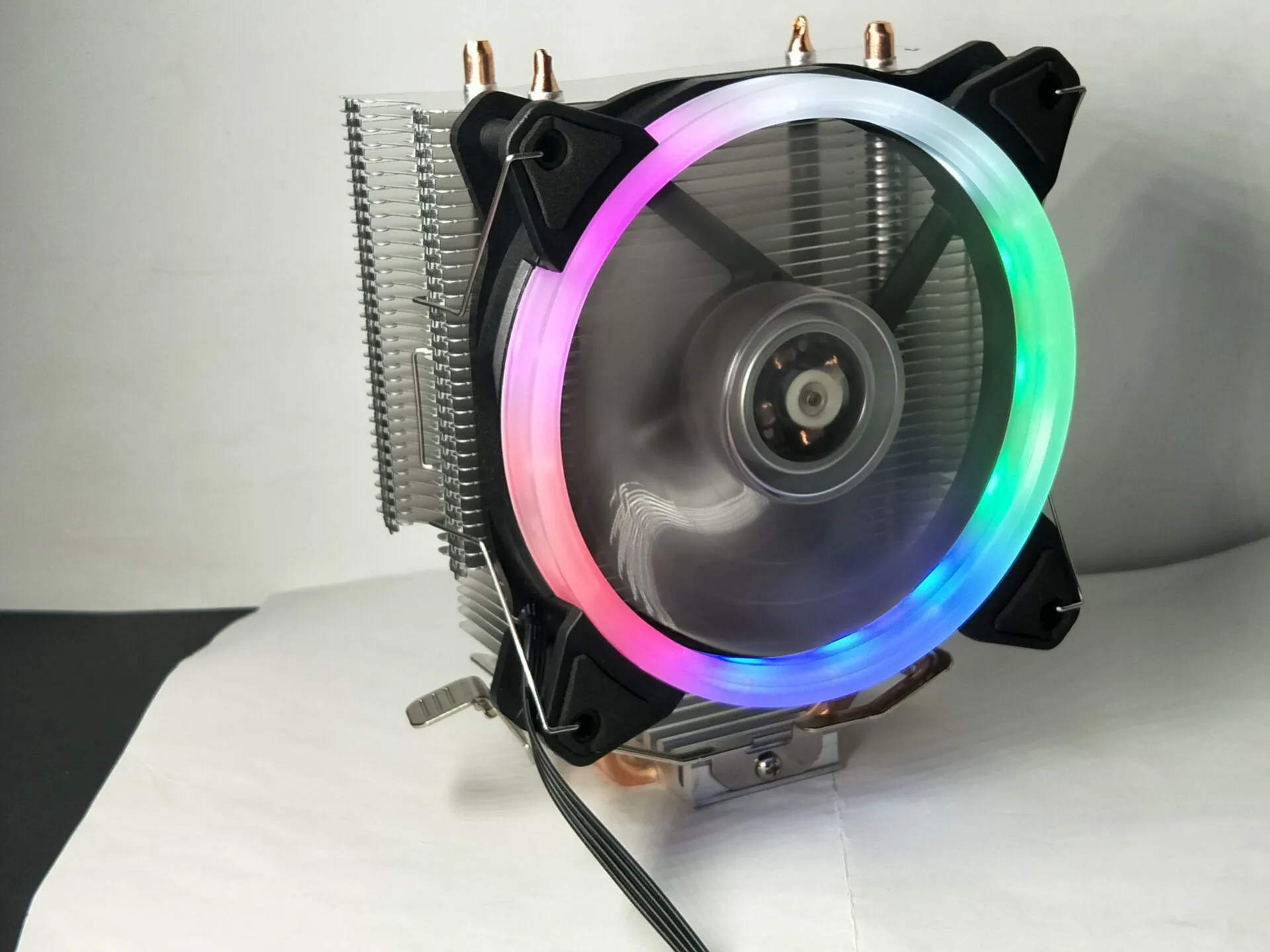

For example, CPU heat sinks, GPU heat sinks, LED lighting heat sinks, and car heat sinks in computers all rely on the support of heat sinks.

They ensure normal operation and prolong the service life of the equipment by effectively dissipating the heat generated by the equipment.

Get Your Free Quote

Your Submit is 100% secure!