Advantages and Characteristics

- High precision: ensuring accurate size and shape of accessories, improving the performance and reliability of the entire vehicle.

- High efficiency: High degree of automation, shortened production cycle, and improved production efficiency.

- Personalized customization:Personalized design and processing are carried out according to customer needs to meet the needs of different riders.

- Strong durability: After precise processing and surface treatment, the accessories have better durability and corrosion resistance.

Product Detials

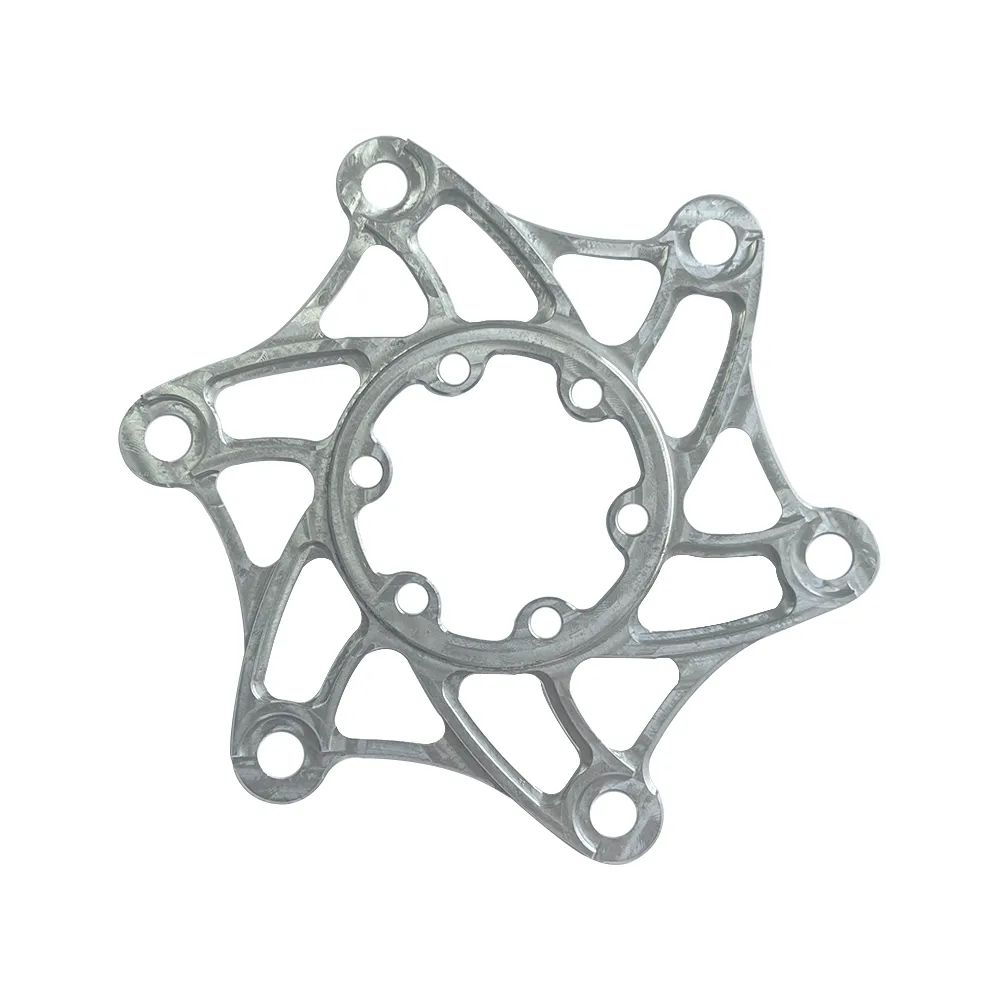

Suitable for off-road and various mountain bike rides. Accessories made of aluminum alloy can maintain stable performance under various weather conditions and are lightweight, which helps reduce the overall weight of the vehicle and is a universal choice.

Machining accuracy

CNC machining technology can achieve high-precision machining, and for mountain bike accessories, the machining accuracy can usually reach 0.005mm or even higher.

This high-precision machining can ensure that the size and shape of the accessories

meet the design requirements, improving the performance and reliability of the entire vehicle.

Application Fields and Product Types

CNC mountain bike processing parts are widely used in various parts of mountain bikes

- Frame: CNC machined frames can achieve lightweight design while maintaining sufficient strength and rigidity.

- Stand: CNC machined stands can be personalized according to the rider’s height and riding style, improving riding comfort and handling.

- Cranks: CNC machined cranks have precise dimensions and shapes, ensuring efficient and stable power transmission.

- Wheel set: CNC machined wheel set components, such as hubs, spokes, etc., can enhance the overall performance and durability of the wheel set.

- Braking system: CNC machined brake clamps, brake discs, and other components can provide better braking performance and safety.

Zence bike accessories – application 2

Get Your Free Quote

Your Submit is 100% secure!