Advantages

Our CNC machining centers play a crucial role in automotive parts, especially when dealing with engine components that require extremely high precision and surface quality.

These components, such as the crankshaft, camshaft, cylinder head, and cylinder block, are the core components of the engine, and their machining quality directly affects the performance and lifespan of the engine.

Through its high-precision cutting capability, CNC machining centers can ensure that the dimensional accuracy, shape accuracy, and positional accuracy of these components meet the design requirements while ensuring that the surface roughness meets strict process standards.

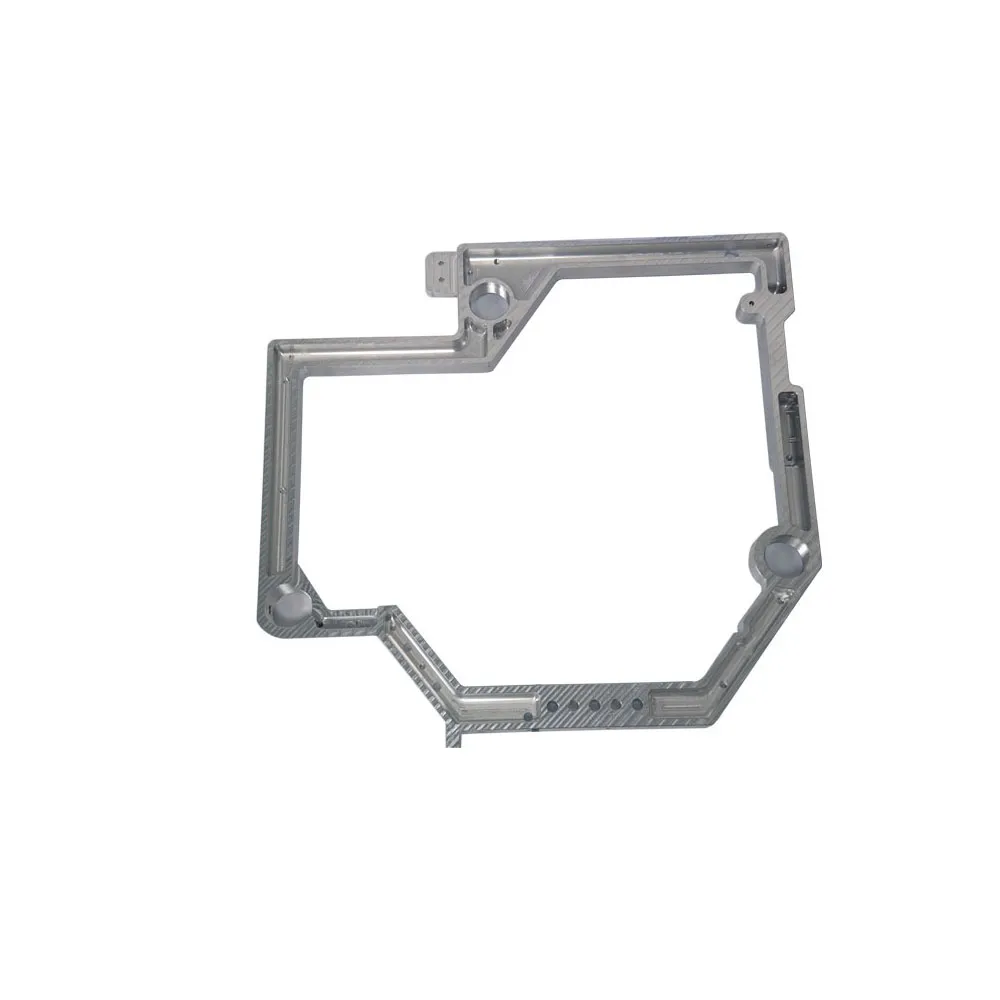

Product Detials

In addition, Our CNC machining centers also can process complex shaped components.

For example, complex blade shapes, precise contours of pistons, and complex curved surfaces of connecting rods, which are difficult to achieve in traditional machining methods, can be easily completed through precision programming and high-speed cutting technology of CNC machining centers.

This ability not only improves production efficiency and processing accuracy but also greatly enriches the design possibilities of products, enabling manufacturers to produce more complex and powerful components.

Get Your Free Quote

Your Submit is 100% secure!