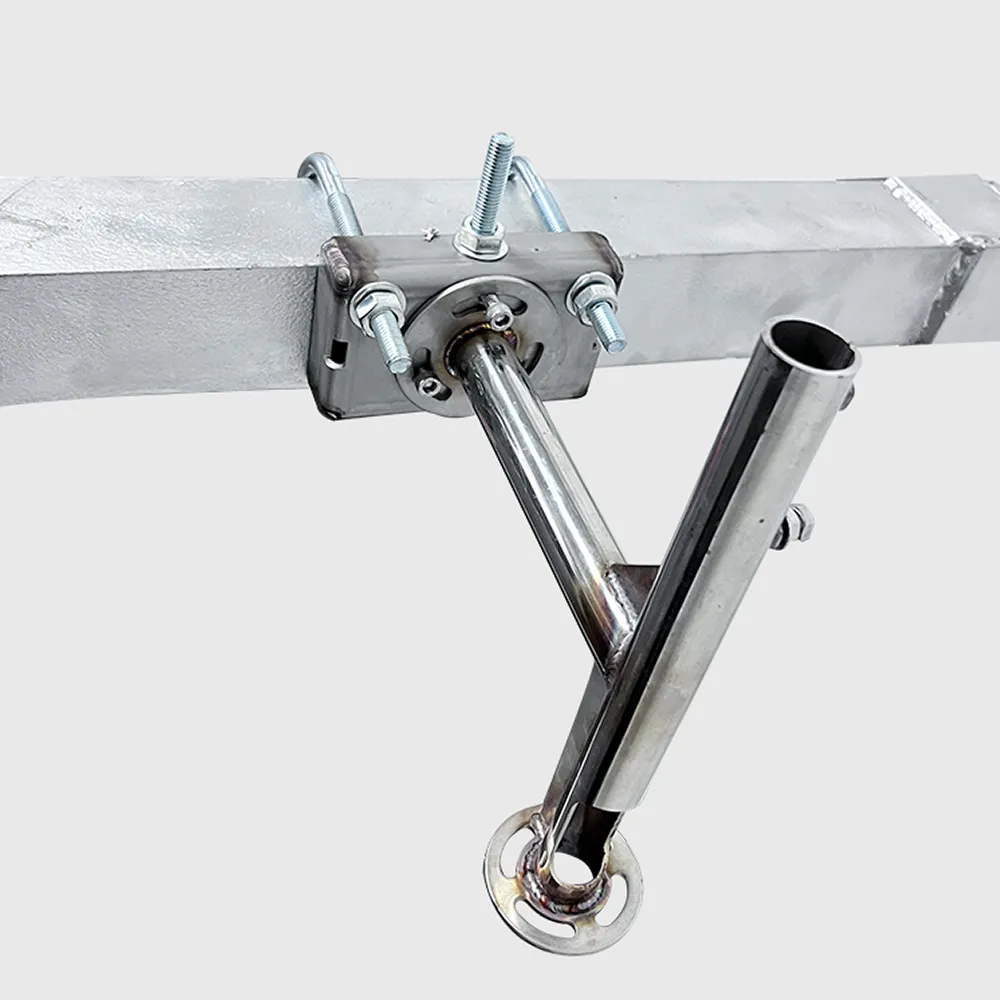

Application of sheet metal bracket

The main function of sheet metal brackets is to provide stable and reliable support and fixation, ensuring that equipment or components can operate normally.

- In the construction industry, it is used to support and fix various equipment and materials;

- In the power industry, it is used to support and fix equipment such as utility poles and cables;

- In the communication industry, it is used for installing and maintaining communication equipment.

Product Detials

Manufacturing process

Cutting:

Select suitable materials according to the product design drawings and cut them into the required board size. During the cutting process, it is necessary to ensure that the material specifications and quality meet the production requirements, and the cutting size accuracy should be controlled within a certain range.

Bending:

Using bending equipment to bend the sheet metal into a predetermined outline. During the bending process, it is necessary to select a suitable bending machine and determine parameters such as bending radius and angle to ensure that the support structure is reasonable and the strength is reliable.

Welding:

Various components are welded together using welding techniques to assemble a complete support structure. During the welding process, it is necessary to choose appropriate welding methods such as TIG, MIG, laser welding, etc., and determine welding current, voltage, speed and other parameters to ensure stable and reliable welding quality.

Surface treatment:

In order to improve the corrosion resistance and aesthetics of the bracket, surface treatment is usually required. Common surface treatment methods include spraying, electroplating, anodizing, etc. These treatment methods can form a protective film on the surface of the bracket, improving its corrosion resistance and durability.

Classification of sheet metal brackets

Classified by shape:

Sheet metal brackets can be classified according to their shapes, such as L-shaped brackets, U-shaped brackets, Z-shaped brackets, etc. Each shape of bracket has its specific application scenarios and advantages.

According to the purposes of the bracket, it can be divided into equipment bracket, pipeline bracket, electrical bracket, etc. These brackets are used to support and secure different types of equipment and components.

Classified by material:

Sheet metal brackets can be made of various metals, such as stainless steel, carbon steel, aluminum alloy, etc. Brackets made of different materials have different performance characteristics.

For example, stainless steel brackets have excellent corrosion resistance and a beautiful appearance, while aluminum alloy brackets are lightweight, beautiful, and easy to process.

Application area

- Construction industry

In the construction industry, sheet metal brackets are used to manufacture various metal components such as window frames, door frames, ladders, stairs, guardrails, steel structures, etc. These components play a supporting and fixing role in construction projects, ensuring the stability and safety of the building.

- Electronics and Electrical Industry

In the electronics and electrical industry, sheet metal brackets are widely used for supporting and fixing components such as chassis, cabinets, various electronic equipment casings, panels, etc. Sheet metal brackets can produce fine parts that meet the precision and strength requirements of electronic and electrical equipment.

- Mechanical equipment manufacturing industry

In the mechanical equipment manufacturing industry, sheet metal brackets are used to make various mechanical equipment components such as shells, brackets, partitions, etc. These components need to withstand the weight of mechanical equipment and vibrations during operation, therefore requiring sheet metal supports to have sufficient strength and stiffness.

Get Your Free Quote

Your Submit is 100% secure!